THE 50¢ ELECTROCUTION HAZARD!

What is a 50¢ electrocution hazard? A Pointed Screw! Far Fetched? – Not Really! Common? – YUP! What is an improper screw type? SHARP! What is worse than that? L-O-N-G & SHARP! Just like these 2 inch long screws we found in a panel last week. … Continue reading →

What is a 50¢ electrocution hazard?

A Pointed Screw!

LONG SHARP SCREWS!

Far Fetched? – Not Really!

Common? – YUP!

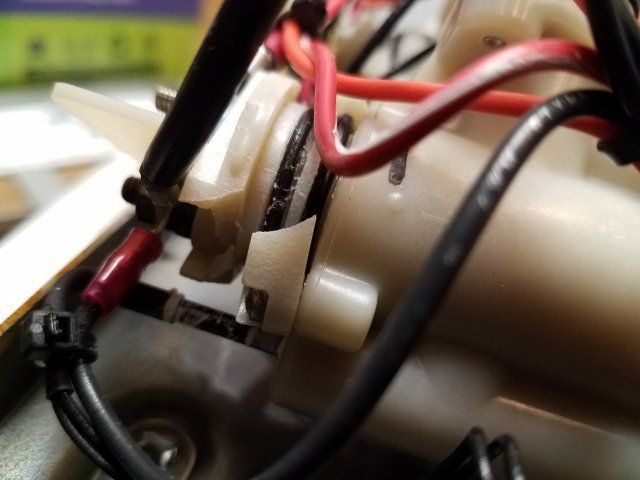

What is an improper screw type? SHARP! What is worse than that? L-O-N-G & SHARP! Just like these 2 inch long screws we found in a panel last week. When I say sharp I am talking about 2 things. the first one is POINTY, the second type is designed to cut, a.k.a. “self-tapping”.

Seemingly so innocuous, so unsuspecting… When used to attach the panel cover, a screw selection could be a really dangerous decision. We have had a little run of pointy screws in electrical panels lately. They are common and potentially dangerous. It isn’t anything new, nor can we predict when or where they will turn up. The problem originates from carelessness. Somebody looses one or more screws that came with the panel and being resourcefully cheap, replaces them with whatever they can find and force to fit. We have seen fine threaded metal screws, drywall screws, self tapping metal screws, wood screws, and probably a few others. These “improper screw types” are utilized in a pinch to get the exposed wiring covered up in a hurry.

Inappropriate Screws

So, what is the risk? Well, the risk is electrocution or fire. These improper screws can pierce the plastic insulation that protects the “hot” conductors in the electrical panel. Not only do they have the potential to pierce the wires, but being metal, they conduct electrical current from the hot wire to the big metal box in front of your face. Thank God for breakers. If the breaker is working, this short-circuit condition is brief and ameliorated promptly. But what if the breaker is bad and malfunctions? Bad news for you buddy! This could result in severe electrocution or a fire that would hopefully be contained inside the UL rated electrical panel. Was the UL rating compromised via unnecessary holes, or missing connectors? That is another article.

GOOD PANEL SCREWS! While doing home inspections in Middle Tennessee, we witness plenty of pointy screws in panels. Have we witnessed short circuits? Pop, Spark, Bang! YUP! It is unsettling I might add. So, what have I learned by experience? Upon approach, I touch the cover with the back of my hand. Should I be shocked, I would flinch away from the panel and not inadvertently grasp said booby trap. I can usually spot aftermarket screws as the heads look different. Frequently, someone has added a washer to the aftermarket screw as the head is too small and slips through the oversize hole on the cover. If I get a spark, pop, bang, or tripped breaker, I stop and baptize the panel as “unsafe.” This undesirable condition is better left to a licensed electrician who has made different life decisions. Never put sharp screws back in a panel or they might pierce the wiring insulation. If you need to purchase replacement screws – USE THESE.

Inspector Aaron Schroer

Seeing – Knowing – Caring